Innovative Textile Solutions

Quality Textiles And

Beautiful Designs

Innovative Textile Solutions

Quality Textiles And

Beautiful Designs

Learn More

About Swavelle Group

Swavelle Group is one of the most diverse textile suppliers in the industry. We are a designer, domestic manufacturer, and convertor of six diverse brands of textiles to service the Contract, Outdoor, Residential, and RV Markets.

Our Brands

Swavelle

The finest array of beautifully designed fabrics for virtually every decorating need. Our wide range includes delicate embroideries and lofty textures to prints and wovens.

Custom Design & Color Capabilities

Custom Design & Color Capabilities

TFA

Luxurious high-end decorative fabrics with impeccable attention to detail curated especially for the furniture industry.

Custom Design & Color Capabilities

Custom Design & Color Capabilities

Swavelle USA

Exceptional designs, sustainably made with certified recycled yarns serving the residential and contract markets.

Custom Color Capabilities

Custom Color Capabilities Handmade Comfort

Handmade Comfort Certified Recycled Yarns

Certified Recycled Yarns Sustainable

Sustainable Upcycled

Upcycled Made in the USA

Made in the USA

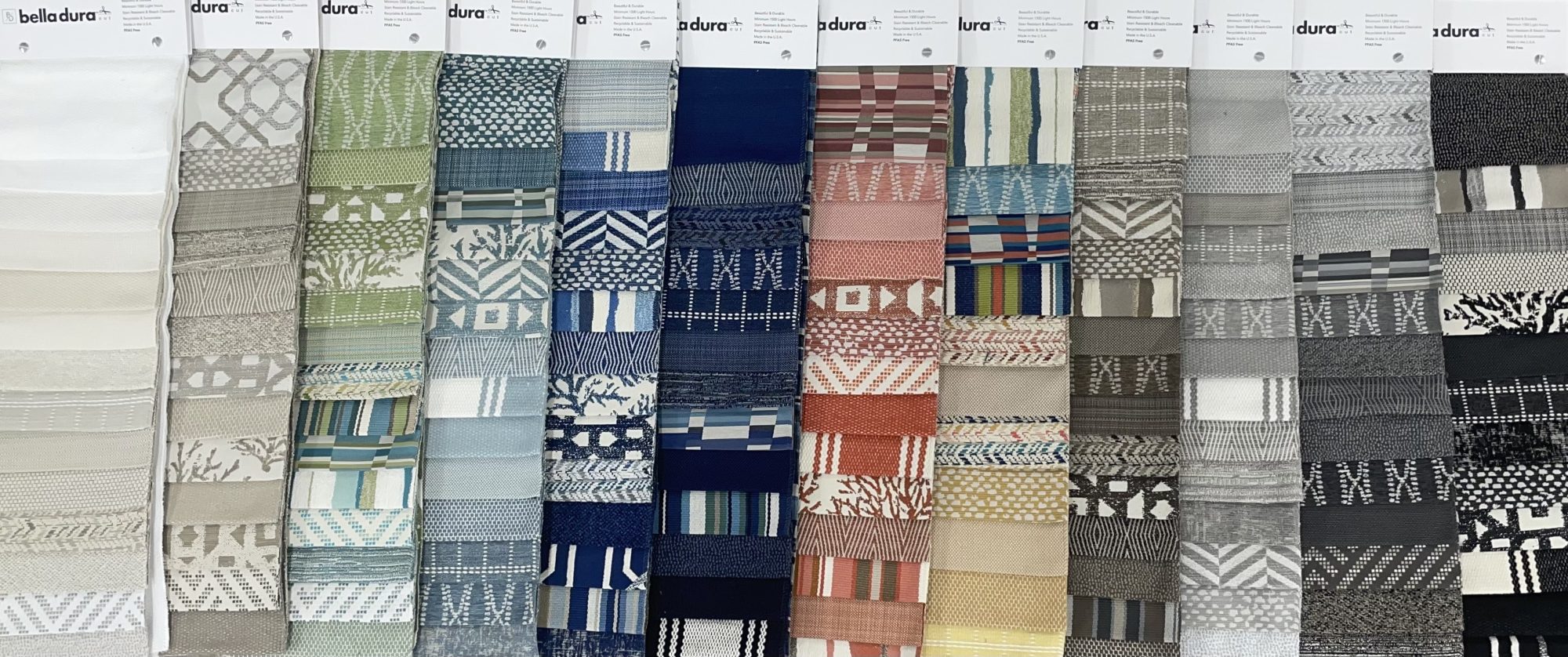

Bella Dura Home

Indoor/Outdoor Performance fabrics offering unparalleled style and durability for worry-free living.

Beauty & Performance

Beauty & Performance Indoor/Outdoor

Indoor/Outdoor Fade Resistant

Fade Resistant  Easy to Clean

Easy to Clean Made in the USA

Made in the USA

Bella Dura

The ultimate contract grade performance fabric. Engineered with solution dyed yarns to withstand the toughest demands while being design forward.

Beautiful & Durable

Beautiful & Durable Minimum 1500 Light Hours

Minimum 1500 Light Hours Stain Resistant

Stain Resistant Bleach Cleanable

Bleach Cleanable  Recyclable

Recyclable  Sustainable

Sustainable Made In The USA

Made In The USA

Swavelle USA Contract

Created to be design forward in look and function, this line of contract-grade fabrics is highly durable and sustainable.

Refined Designs

Refined Designs High Abrasion

High Abrasion Certified Recycled Yarns

Certified Recycled Yarns  Sustainable

Sustainable Made in the USA

Made in the USA

Swavelle

The finest array of beautifully designed fabrics for virtually every decorating need. Our wide range includes delicate embroideries and lofty textures to prints and wovens.

Custom Design & Color Capabilities

Custom Design & Color Capabilities

TFA

Luxurious high-end decorative fabrics with impeccable attention to detail curated especially for the furniture industry.

Custom Design & Color Capabilities

Custom Design & Color Capabilities

Swavelle USA

Exceptional designs, sustainably made with certified recycled yarns serving the residential and contract markets.

Custom Color Capabilities

Custom Color Capabilities Handmade Comfort

Handmade Comfort Certified Recycled Yarns

Certified Recycled Yarns Sustainable

Sustainable Upcycled

Upcycled Made in the USA

Made in the USA

Bella Dura Home

Indoor/Outdoor Performance fabrics offering unparalleled style and durability for worry-free living.

Beauty & Performance

Beauty & Performance Indoor/Outdoor

Indoor/Outdoor Fade Resistant

Fade Resistant  Easy to Clean

Easy to Clean Made in the USA

Made in the USA

Bella Dura

The ultimate contract grade performance fabric. Engineered with solution dyed yarns to withstand the toughest demands while being design forward.

Beautiful & Durable

Beautiful & Durable Minimum 1500 Light Hours

Minimum 1500 Light Hours Stain Resistant

Stain Resistant Bleach Cleanable

Bleach Cleanable  Recyclable

Recyclable  Sustainable

Sustainable Made In The USA

Made In The USA

Swavelle USA Contract

Created to be design forward in look and function, this line of contract-grade fabrics is highly durable and sustainable.

Refined Designs

Refined Designs High Abrasion

High Abrasion Certified Recycled Yarns

Certified Recycled Yarns  Sustainable

Sustainable Made in the USA

Made in the USA

Our mission

Sustainability Is Our

Priority

Sustainability is not a nice to have, it is a must. Being aware of the impact we have on our environment and implementing change is vital-both in our business and our personal lives. It is not one program, it is a forever commitment.

The Swavelle Group is committed to being:

-

Environmentally responsible

Environmentally responsible -

Socially awakened

Socially awakened -

Economically aware

Economically aware

Custom solutions

Helping Your Vision Come To Life

Our design team offers custom design development to meet your brand’s aesthetic. With personalized designs, custom printed fabric and colorways, and quick turnaround – the possibilities are limitless.

Contact Us